|

| February 20, 2018 | Volume 14 Issue 07 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Overhung load adaptors provide load support and contamination protection

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Learn more.

Why choose electric for linear actuators?

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Get this informative e-book. (No registration required)

New AC hypoid inverter-duty gearmotors

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Learn more.

Next-gen warehouse automation: Siemens, Universal Robots, and Zivid partner up

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Read the full article.

Innovative DuoDrive gear and motor unit is UL/CSA certified

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

Learn more.

BLDC flat motor with high output torque and speed reduction

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Learn more and view all the specs.

Application story: Complete gearbox and coupling assembly for actuator system

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Read this informative GAM blog.

Next-gen motor for pump and fan applications

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

Learn more.

Telescoping linear actuators for space-constrained applications

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Learn more.

Competitively priced long-stroke parallel gripper

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

Learn more.

Extend your range of motion: Controllers for mini motors

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

Learn more.

When is a frameless brushless DC motor the right choice?

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

View the video.

Tiny and smart: Step motor with closed-loop control

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Learn more.

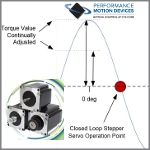

Closed loop steppers drive new motion control applications

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

Read this informative Performance Motion Devices article.

Intelligent compact drives with extended fieldbus options

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

Learn more.

Next big breakthrough in robotics? Northeastern U. researchers say it's all about dexterity

[Credit: Northeastern University]

By Bill Ibelle and Allie Nicodemo, Northeastern University

While drones and driverless cars dominate the headlines, another breakthrough -- robot dexterity -- is likely to have an even greater impact in both business and everyday life.

"Robot manipulation is the next shoe to drop," says Robert Platt, computer science professor and head of the Helping Hands robotics lab at Northeastern. "Imagine a robot that can do things with its hands in the real world -- anything from defusing a bomb to doing your laundry. This has been a dream in the research community for decades, but now we're finally getting to the point where it could actually happen."

Recent advances in machine learning, Big Data, and robot perception have put us on the threshold of a quantum leap in the ability of robots to perform fine motor tasks and function in uncontrolled environments, says Platt.

It's the difference between robots that can do repetitive tasks in a highly structured factory environment and a new era of humanoid robots that can do meaningful work in the real world.

Why fine motor skills have lagged

There's an irony in the field of robots and artificial intelligence known as Moravek's Paradox: What's hard for humans is relatively easy for robots, and what's easy for humans is nearly impossible for robots.

We can program a robot with the computational skills to defeat an international chess champion, but struggle to give it the dexterity of a 2-year-old child. Identifying and grabbing a pencil in a random pile of office supplies is nearly impossible for a robot, and opening a door and walking into a room -- as demonstrated in this recent international robot competition -- can look like a scene from a slapstick comedy.

VIDEO: What happens when robots lack fine motor skills? See lots of droids take a tumble at the DARPA Robotics Challenge Finals in 2015. [Credit: IEEE Spectrum/Northeastern University]

Because humans have been evolving their visual, sensory, and motor skills for millions of years, these complex movements are so deeply ingrained in human circuitry that we perform them unconsciously. In contrast, high-level endeavors such as mathematics, science, and stock analysis are relatively recent human endeavors -- so they're much easier for engineers to replicate.

Poised for a breakthrough

In spite of the enormous challenge, Platt says autonomous robots are poised to make huge leaps in their ability to manipulate unfamiliar objects.

For example, Platt and his team at the Helping Hands Lab have trained a robot to find, grab, and remove unfamiliar objects from a pile of clutter with 93 percent accuracy. Achieving this required significant advances in machine learning, perception, and control.

The researchers used a technique called reinforcement learning in which the robot learns via trial and error. They created a simulated world in which the robot could practice picking up and manipulating objects in virtual reality. When the robot did what the researchers wanted -- grabbed an object from a pile -- it was given a reward. This technique allows the robot to master skills in a virtual environment and then apply them to the real world.

A major advance in depth perception was also essential for robots to work in an uncontrolled environment. Previously, they could only see the world as a flat field of seemingly random colors. But with this new 3D perception, they could identify individual objects in a crowded field.

While vision is an excellent tool for guiding broad movements, fine motor skills require a sense of touch.

"Think of what you can do with gloves on," explains Platt. "You can open the garage door, grab a shovel, and clear the driveway. But if you need to unlock the garage first, you need to take your gloves off to insert the key."

As part of a NASA grant, Platt's lab recently built a robotic hand equipped with tactile sensors and developed new algorithms for interpreting the tactile data.

"In order to insert a key into a lock, the robot needs to know exactly how it's holding the key, down to the millimeter," says Platt. "Our algorithms can localize these kinds of grapsed objects very accurately."

Platt's lab demonstrated these new capabilities by grasping a USB connector and plugging it into a port. While this may not sound like a big deal, it's a critical step toward creating robots that can do precise manipulation tasks such as changing the battery in a cell phone.

What's coming?

As with any fledgling advancement -- radar, the telephone, the internet -- the practical applications of robot dexterity are hard to predict. But here are a few:

Home

Platt's Helping Hands lab -- in collaboration with the University of Massachusetts Lowell and the Crotched Mountain Rehabilitation Facility in New Hampshire -- is building a power wheelchair with a robotic arm that can grasp items around the house or perform simple household tasks. This could enable elderly or people with disabilities to continue to live independently in their homes.

Platt is also interested in adapting this technology for everyday use. "We hear a lot about the Alexa-style assistants that can answer questions by accessing the internet. But these assistants can't do anything physical," says Platt. "We want to equip these devices with a robotic body so you can say, 'Alexa, get the newspaper,' or 'Alexa, clean up Jimmy's room.'"

Outdoors

Engineering professor Hanumant Singh, in collaboration with Platt, is building a golf cart-size mobile robot equipped with a robotic arm that can drive around Northeastern's campus autonomously and perform simple manipulation tasks like taking out the trash.

Military

Similar types of robots could take on similar duties in areas of intense conflict and be used for dangerous operations such as defusing mines. For example, Platt and his group recently completed a grant from the Office of Naval Research to develop fundamental manipulation technologies that will be used aboard Naval vessels.

Hazardous waste

Engineering professor Taskin Padir and his team received a grant from the Department of Energy to adapt NASA's Valkyrie robot for hazardous waste disposal. There are more than a dozen sites scattered around the United States where radioactive waste was buried in tunnels during the Cold War. For autonomous robots to locate, grasp, and place this waste in safe containers, they will need fine motor skills and an ability to operate in unfamiliar environments.

Medicine

Funded by a grant from the National Science Foundation, engineering professor Peter Whitney is working with researchers at Stanford University to create a robot that can perform MRI-guided surgery.

Space exploration

Platt is working with researchers at NASA to develop robotic manipulation capabilities for handling soft objects on future NASA space missions.

"Robots that work flawlessly in the lab break down quickly when they're placed in unfamiliar situations," says Platt. "Our goal is to develop the underlying algorithms that will allow them to be more reliable in the real world. Ultimately, this will fundamentally change the way we think about robots, allowing them to become partners with humans rather than just machines that work in far-away factories."

Published February 2018

Rate this article

View our terms of use and privacy policy